Daily Archives: May 29, 2013

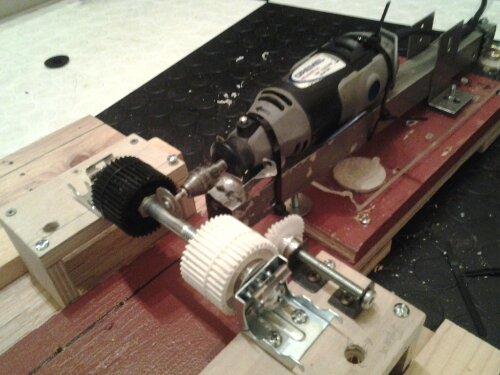

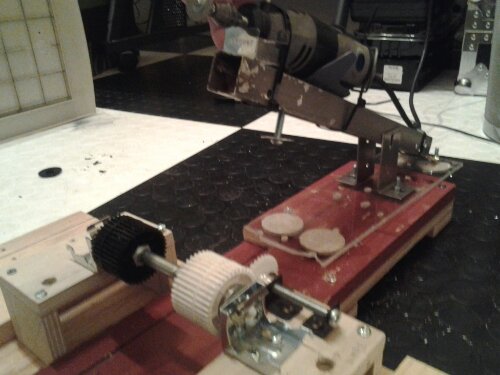

Hodge Podge Bolt Hobbing Mechanism

I decided that I wanted to experiment with different hobbed bolts with some kind of repeatability. So I dug in my scrap heap and came up with this. To make it I used scap plywood, metal tube, corner braces, nuts, bolts, plexi scraps, gears from a printer, blinds clips, dremel, a hinge and some l brackets. The gears are used so I can accurately determine rotation. The hinge work to cut accurately and I also fixed a washer and bolt under the dremel mount so I can adjust for depth. I have yet to try it out yet as I will get time later on to do so.I thought I would post it on here and maybe give some people some ideas for future scrap builds. I’ll update once ive made some hobbed bolts. Im currently messing with different cutting ends and techniques to determine what kind of hobbed bolt etc I want to make.

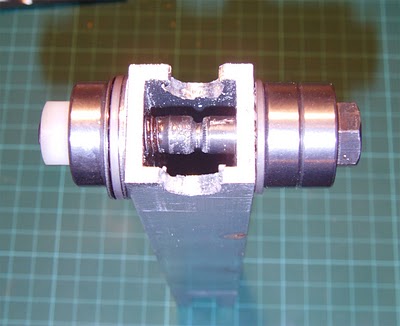

figured I would add how the groove is made before you cut the teeth. It can be made several ways. The way that ive found most convenient for me is to put the bolt or all thread rod in a chuck of a drill. I use to bearings to keep it in position much like you would do if you are tapping the bolt. I have one person hold the drill while I hold a file in the location ive determined to hobb. One person will give power to the drill so that it spins away from you and the file. Make sure you hold the file tightly in one location so it doesn’t skip around. Continue to file to desired depth. Note: I use a round file that is about 3-4mm in width and it has worked well for me in the past. It comes down to personal preferences. Also I highly recommend practicing because without practice more thqn likely you will mess up your first few times. After you have done this then you will be ready to cut the grooves using a dremel, tap, lathe or other tool of preference.